Welcome to the world of Indian wood block printing! Every Saffron Marigold block print comes to life thanks to this heritage craft. Our collections of fair trade block printed linens have stories to tell within their folds. Journey with us to the origins of block printing in India and see how we create a block print on fabric.

What is block printing?

Block printing refers to the printing technique of pressing and stamping fabric with carved wooden blocks filled with color. “Hand blocked” or “hand block printing” are other terms that refer to block printing.

We celebrate the art of block printing on fabric. Our artisans take our original block print designs and print them onto cotton. However, the block printing process goes beyond pressing blocks onto fabric. There are so many steps involved, from carving each wooden block to preparing fabric, mixing dyes, and applying final touches. Each block printing technique requires artistry, skill, and patience. It is the sum of these tasks that produces our gorgeous block printed fabrics.

Woodblock carving for a block print

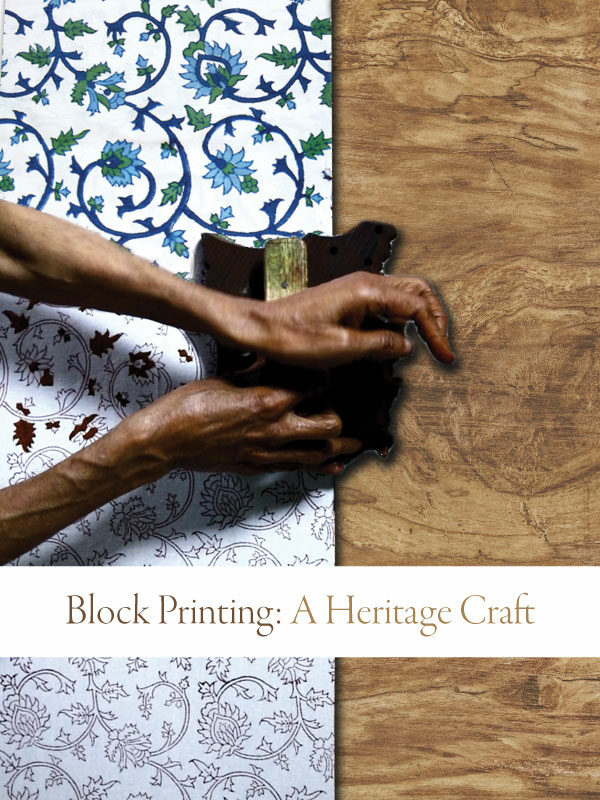

Hand-carved wooden blocks provide the cornerstone of the block printing process. Block carving is tedious, and it demands an exceptional degree of craftsmanship. Wood carvers practice and teach the block carving craft over generations.

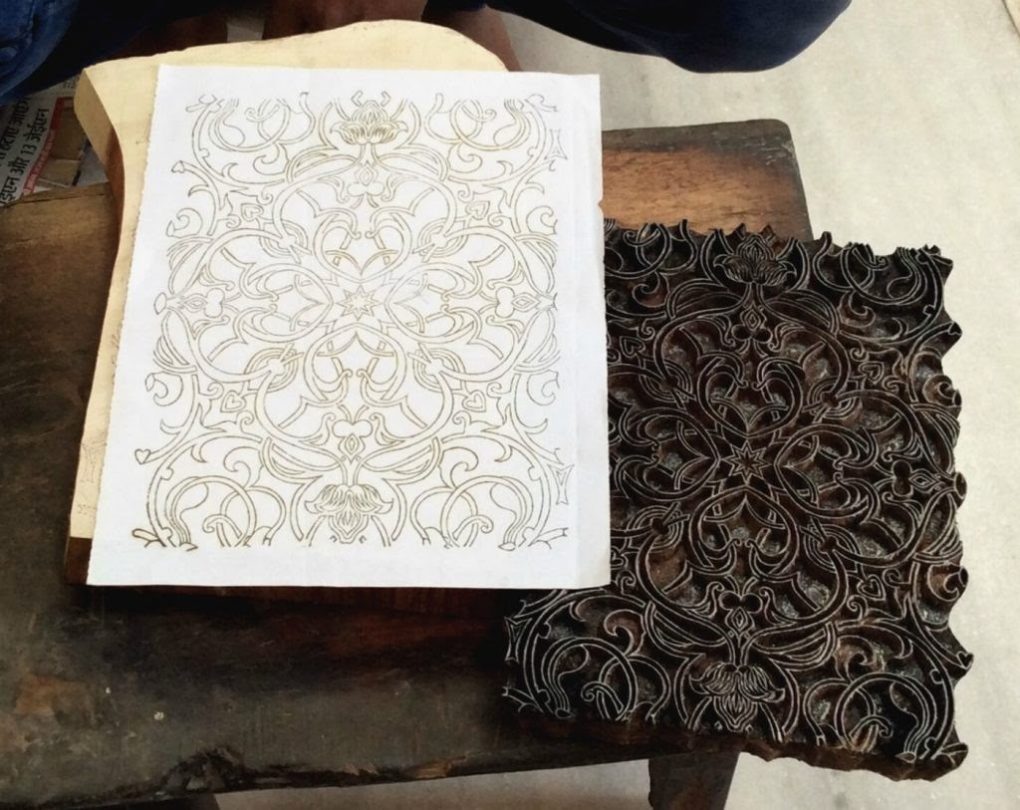

Carving the outline block is the most challenging step in the process of block printing. As the skeleton for the design, it’s the most expensive block. The most skilled artisan in a block making shop (often the owner) works on this piece. Work begins with a freehand paper drawing of the design’s outline. Using the drawing as a map, the artisan traces out the color fill blocks.

Craftsmen trace the design onto a planed slice of shesham wood, which is the best wood for this kind of printmaking, and chisel it 1/3-inch deep. The precision that a master block maker achieves with simple tools is extraordinary. These block printing tools may be simple, but they create something extraordinary. The resulting woodblocks are works of art in themselves!

How many blocks does it take to create a print? Well, that depends on the design. Each color and each design element requires its own separate block. That’s right: each tiny element comes to life one color and one block at a time! You can try to estimate the number of blocks used by tallying the number of colors and design components. A simple design might require just three blocks, but a complex design might need up to 30 blocks!

A woodblock usually ranges between 5–8 square inches. At times, it can be as large as 14 inches if a design requires it. The size constraint of the blocks defines the parameters of viable design, and this is why small motifs characterize Indian block prints.

Wood block preparation

Carved blocks absorb moisture during the printing process, and it’s critical that the wood doesn’t warp. To prevent warping, the blocks stand in trays of mustard oil for a few days. They drain over wads of fabric for several days more cure.

Block carvers then drill tiny holes into areas intended for application of flat color. Stuffing cotton into these holes at the time of printing ensures even color application.

To block print a design, artisans fill each element one block and one color at a time. They also use separate sets of blocks to create the fabric borders. Just like the main design, a border design might require multiple sets of carved wood blocks.

Block printing on fabric: preparation

If you’re a fabric lover, you may already know that most fabric projects require a certain degree of preparation. Block printing onto fabric does, too, but the process is highly involved. Prior to printing, the cotton takes an immersive bath in a gentle bleaching solution. Next, it passes through a dye vat and between two rollers that squeeze out excess dye.

Lastly, the linen dries on tall bamboo frames in the hot Rajasthan sun. Once it’s dry, it heads to the finishing units where hot roller presses smooth the block printed fabric.

Craftsmen measure the fabric, then cut and pin it onto padded 5-meter-long tables. Each product is measured, cut, and printed one at a time! (Did you ever know that so much was involved in block printing fabrics?)

Creating colors for woodblock printing

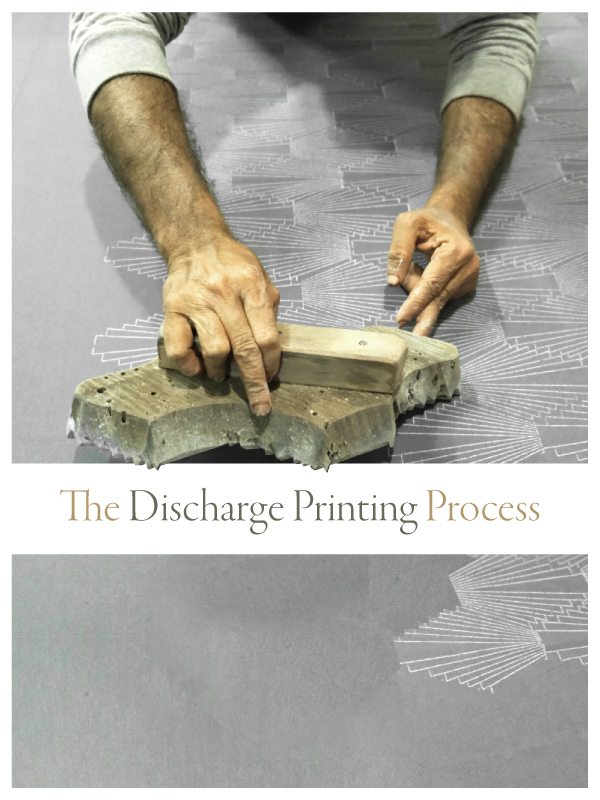

Part of the woodblock printing process includes making determinations about the best dyeing technique for the design at hand. Some warrant easy-to-mix pigment dyes while others require the luminous colors achieved by vegetable dyes. Other designs need the color fastness guaranteed by rapid indigo sol and discharge dyes.

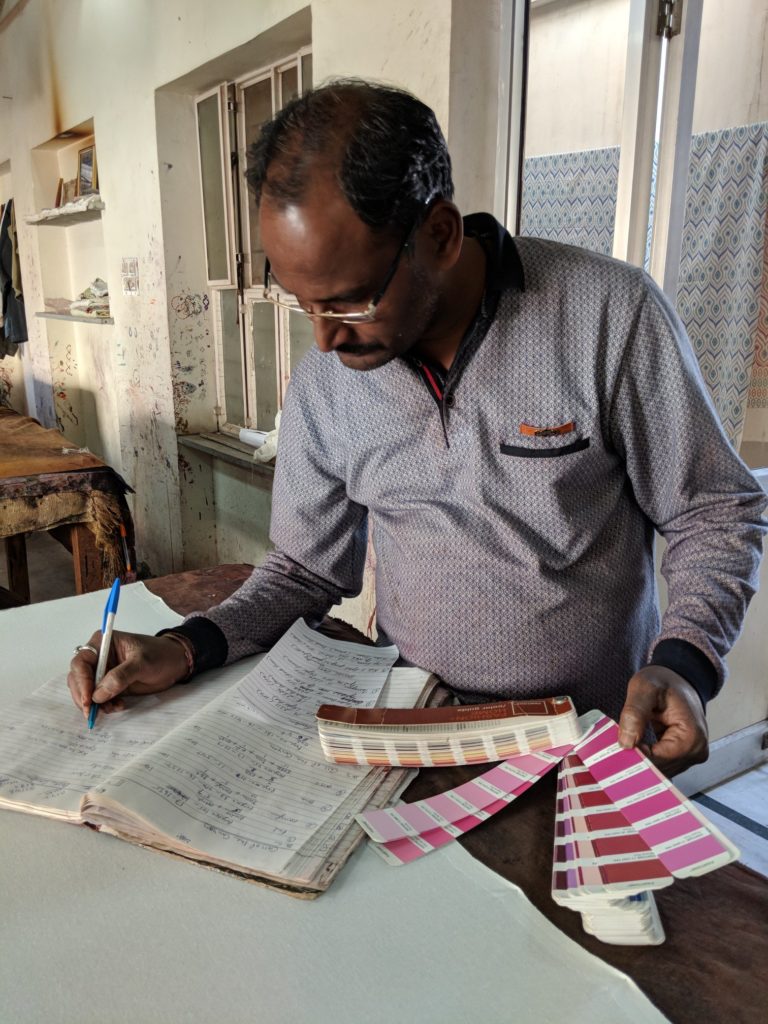

Aided solely by intuition and experience, the color master mixes the colors. He can formulate his color recipe just by looking at the requested Pantone shade!

After mixing and testing the dyes, it’s time to prepare the dye pad. A dye pad consists of a rectangular wooden tray fitted with a metal frame wound with yards of nylon rope. (The taut rope mesh supplies a spring effect during printing.) Several layers of coarse sacking material pile on top of the rope mesh. The final layers are pieces of finer fabrics like silk, chiffon, or voile. The choice of the final layer depends on the dye saturation required for printing.

Next, we pour dye into the pads and even out the surface of the dye pad with a wedge of wood. At this point, we distribute the woodblocks color-wise among carts and organize them in the order of printing.

The block printing technique

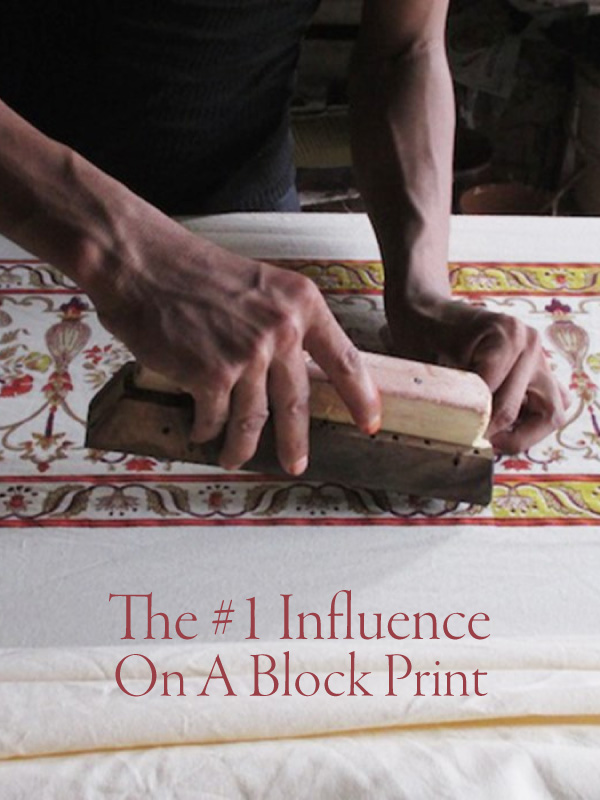

Placement plays an important role when it comes to block printing techniques on fabric Printing follows an outside-in orientation: the border is printed before the main design. Before using any of the color blocks, artisans print the outline of the design. The block printer dips the outline block into the dye pad and moves down the length of the table. He carefully places the block onto the fabric and then strikes it with the heel of his hand.

The block carver chisels registration points on the outline block, which help with aligning the remaining blocks. The printer’s hands are his only tools here—he doesn’t use any other rulers!

These registration marks on block printed fabrics help distinguish them from mass-produced textiles that are often sold under the guise of hand block prints. A close inspection reveals the registration marks, which all authentic block printed textiles have.

The most experienced printer prints the outline since it provides the framework for the design. After printing the outline, he fills in the remaining colors and repositions the block printing fabric.

Finishing Touches

Most printing houses have flat terraces above their studios; this is where finished wood block prints are left to sun for a couple of days to fix the pigments.

Once the textiles are completely dry, they go to the local washing facility. Believe it or not, this is a significant stage in the block printing process: negligence here could ruin an impeccable piece! Cleaners determine the right approach based on the block printing technique used to create the linens.

The washed fabrics return to the studio where they undergo final finishing processes. They are ironed, stitched, and checked for quality. Then they’re finally packed and labelled. The block printed fabrics are now ready to make their long journey around the world from Sanganer to California!

We hope you enjoyed learning about the block printing process, and we hope that you leave this post with a deeper understanding of block print fabrics. If you’d like to see our our collections of Indian wood block prints, simply click here.

Textile patterns created through traditional woodblock printing are part of India’s vibrant visual and material culture.

Every time an artisan’s hand hovers over a textile, the fabric vibrates with life and consciousness as he ponders the placement of each wood block. A simple piece of cotton soon transforms into a living textile that encapsulates within its fibers generations of skill, tradition, craftsmanship, and a way of life.

India’s role in woodblock printing

You might be wondering when block printing was invented since it’s an art form that’s enjoyed a resurgence in recent years. And maybe you’ve wondered where woodblock printing originated, too. The answer: even though woodblock printing remains one of India’s leading heritage crafts and enjoys a strong visual identity worldwide, block printing didn’t actually originate in India. In fact, it all started in China. And although China gave birth to woodblock printing about 4,000 years ago, India adopted and raised the art form.

In India, hand block printed textiles reached their highest visual expression and commercial potential. How did this happen? Well, India developed an unrivaled mastery in the secrets of natural plant dyes and mordants. This expertise enabled Indian printers to create unique designs and a color palette that became the envy of the world. Here, the tropical climate helped dyes could bloom to their deepest expression. Only in India could one find such intoxicating reds, rich blues, and saturated blacks. These were the prized creations of the dyers’ art.

Combine this ability with countless invasions and a diverse indigenous population and you can see how India came to possess an expansive printing pattern vocabulary. Suffice it to say that India’s unique history made a lasting imprint on the art of block printing!

A brief history of block printing

No discussion on the history of block printing in India can take place without mentioning the Mughals. The ‘heyday’ of hand block printing came during the reign of the Mughal Empire (1526-1857). The Mughals enjoyed an immense consumption of textiles, which were status symbols at the time. Since coinage was in short supply, cloth exchanges served as barter, underpinning the economic structure of the Empire.

Indian block printing’s pattern repertoire stands as one of the Mughals’ legacies. Floral patterns featured prominently in Mughal textiles as metaphors for paradise and allusions to eternal gardens. Today’s block printed fabrics still feature this popular theme!

England’s demand for Indian textiles led to an enormous boom that coincided with the golden age of the Mughal Empire. (In fact, the Indian textile industry was at one point charged with draining the British treasury!)

However, Indian hand block printing began to decline at the end of the Mughal Empire and the dawn of industrialization. Along with synthetic dyes came Britain’s sabotage of India’s handmade textile industry. The markets grew saturated with cheap mill-printed cotton. The skills knowledge passed down through generations of artisans was all but lost. The supremacy of the Indian block print ended.

Indian woodblock printing’s appeal to niche markets

While India’s elite always favored hand printed textiles, Indian block printing seemed like a thing of the past to many. That all changed in the flower-power days. The 1960s and 1970s marked a period of revival. The bohemian aesthetic and a fascination with eastern spirituality renewed interest in Indian block prints.

Indian wood block prints today span the spectrum of traditional pattern to modern style. In essence, the prints simultaneously reflect past and present. Woodblock printing, a traditional craft, exists in a parallel universe to the modern world. It’s an art that stubbornly resists industrialization. To this day, artisans practice block printing without machines or computers.

Rajasthan, India: The birthplace of Indian woodblock printing

At Saffron Marigold, we source our block printed textiles from the desert state of Rajasthan. People around the world know this state and its capital (Jaipur) as the birthplace of Indian wood block printing. Jaipur textiles are in high demand across the globe.

Sanganer: a study in contrasts

We work with a family of artisans in Sanganer, a bustling township close to Jaipur. Sanganer is a rural town caught in a time warp. On every street, you’ll find trendy youth texting friends and zipping motorcycles past Hindu temples and camel-drawn carts. (These carts carry the shesham logs and bales of cloth that will become carved blocks and Indian block print fabrics.)

In startling contrast to it lively textiles, Sanganer remains a colorless town filled with unfinished concrete buildings and dusty, narrow paths.

As you step away from the chaotic main roads, you’ll find a thriving ecosystem tucked away in the dusty lanes. Here, fabric dyers, block makers, block printers, washers, tailors, and suppliers work to create the famous block printed textiles of Sanganer.

How Saffron Marigold helps keep Indian woodblock printing alive

Today’s Indian block printing studios cater to niche markets and textile mavens worldwide. Thanks to the slow cloth movement and an interest in handcrafted goods, Indian wood block printing is still alive–but barely.

Saffron Marigold steps in to ensure the survival of this craft for the next generation. At our studio, we encourage young people to apprentice with us, and we pay above market rates. We operate in the spirit of fair trade, believing this legacy keeps us connected, beautiful, and soulful.